There is no better reminder of the dangers of overlooking a failed (or failing) seal in a mechanical device than the fatal disintegration of Challenger, a space shuttle that killed all its seven crew members. The January 1986 incident remains etched in the minds of many of the people who were old enough to witness it.

While disasters of less but significant magnitude continue to happen, they can be easily avoided through such a simple measure as hydraulic seal replacement.

If you are not sure about the importance of regularly having the seal checked for wear and tear, here are few facts that you need to consider:

1. Protect the Environment

It seems obvious, but many people do not consider a damaged seal an environmental hazard. Consider the amount of hydraulic fluids used all over the world. Then allow a sizeable portion of it to drain into the ground and water bodies. Eventually, you will have an ugly picture of a damaged wild and aquatic life, leave alone detrimental health and economic effects to fellow human beings—all this courtesy of a faulty hydraulic seal.

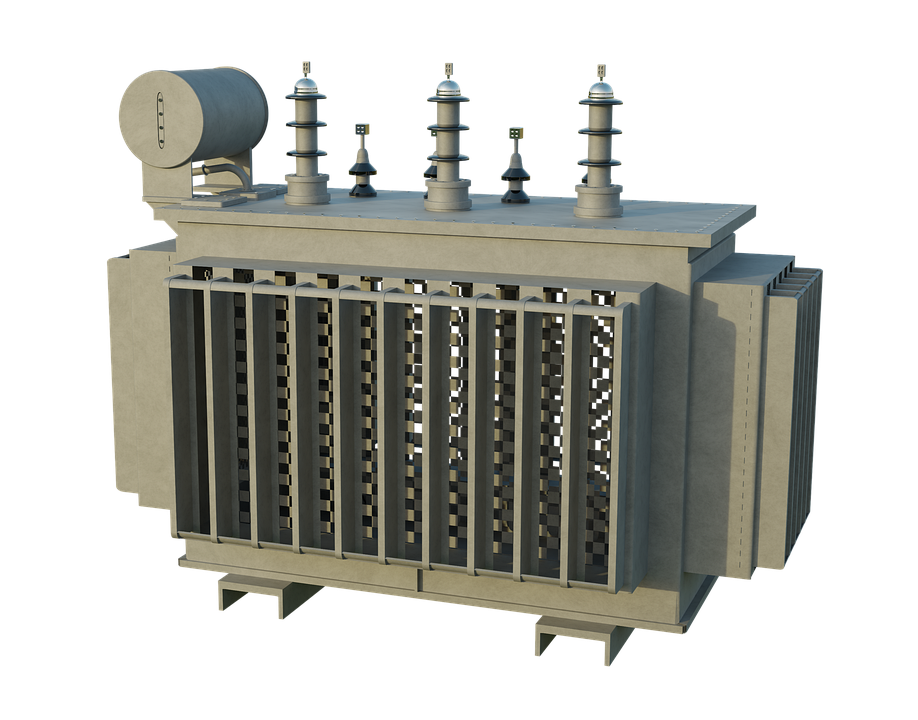

2. Ensuring Optimum Machine Efficiency

According to many machine operators and supervisors, everything is well and good as long the machine is running. This is a huge mistake. An important consideration is regrettably left out —damaged seals directly result into less performance of the machine in question. In other words, you will not be getting as much as you are meant to from the machine if you don’t carry out hydraulic seal replacement. This means that your profit margin will be lower than it is actually supposed to be. It gets worse when there is more than one leakage problem. Put in another way, the higher the number of leaks, the lesser the performance of the affected machinery.

Bottom-line

Hydraulics leaks cost the industrial community millions of dollars every year but the biggest issue associated with this phenomenon is that most industrial management bodies as well management in various industries tend to consider it as a normal wear and tear issue. Well, it is not.

NASA, the organization charged with American space exploration, was fully informed on the high probability of the impending disaster as a result of the faulty O-ring seals but still authorized the space shuttle takeoff. In other words, the machine was allowed to run to its fatal end. Likewise, industrial machinery left to run without proper hydraulic seal check and replacement when there is confirmation of damage will not only lead to financial losses but also bodily harm to workers as a result of slipping and falling.

Leave a Reply