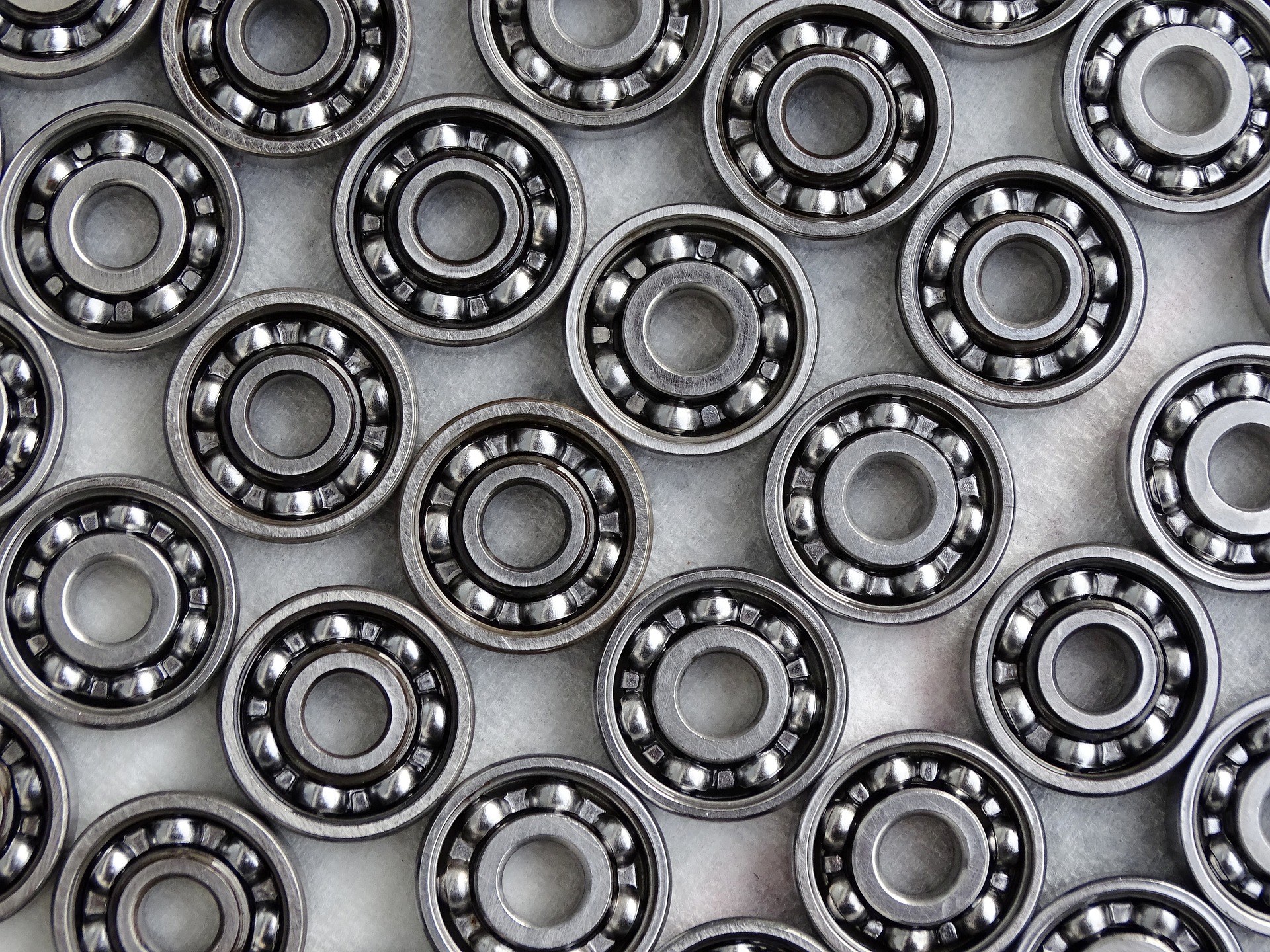

Stone cutting disc machining is a versatile method for producing high-quality cutting edges. Utilizing a stone cutting disc is much faster and easier than employing a computer-controlled CNC machine. A cutting disc is a specialized tool that contains a ball (the cutting element) and a diamond cutter head. When this type of equipment is used, it cuts the stone out of thin sheet material by rotating the diamond cutter head on a predetermined axis. Typically, this type of machine is utilized by professionals to quickly create small, precise machined edges and is often used in abrasive finishing applications.

This type of machine has many advantages. One of which is its ability to produce exceptionally high-quality tool lines and finishes, along with the capability to cut corners and perform complex tasks. Using a cutting disc allows for the production of tool lines that are completely solid, smooth, and free of burrs or ridges. This type of machining can also be utilized to produce precision tooling. Finally, it is often used to create precision angled cuts.

When purchasing a stone cutting disc, there are many important factors to consider. One of which is the material being cut. Discs are available for diamond, garnet, sapphire, and various other types of gemstones. The cost of the disc and its overall size and shape will vary greatly depending on the type of rock being cut.

The second factor to consider is the cutter head design. This is typically referred to as the “cutting disc offset,” “bore ring,” or “disc finial offset.” This term is used to describe the typically employed angles to offset the rough edge of the disc. Also, the stone cutting disc overall size is another factor to consider because the larger the cutter head, the larger the diamond hole will be.

When preparing to cut a stone with a stone cutting device, it is important to use the proper lubrication. Lubrication is crucial when cutting gemstones with metal edges. The most common lubrication method is to spray water onto the cutting area to soften the edges of the stone. If a machine is utilized, then special oil can be added to the oil tank to maximize lubrication properties.

Once the stone cutting tool is in place and secured into place, a rotating sander can be used to perform the final stage of cutting. It is important to wear safety glasses and appropriate protective gear while performing this process. A diamond cutting disc can only cut so much weight per minute, so a manual scan of the surrounding area must first be conducted to determine precisely how much diamond is available to be cut. After this scan, a rough cut can then be made.

Leave a Reply