The Wonders of Studying Electrical Components

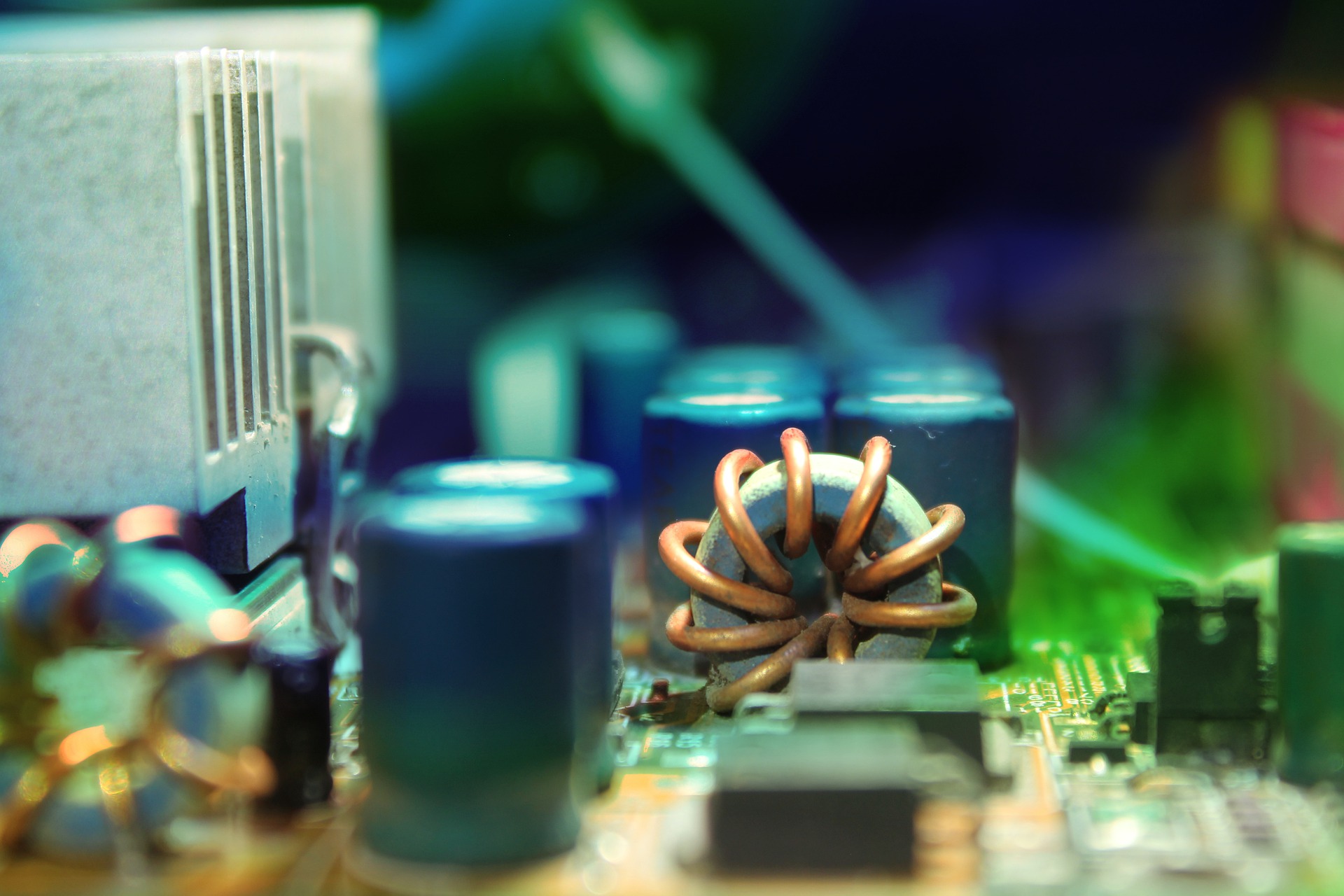

Have you ever wondered how electrical devices work? The answer lies in electrical component research, which is the study of

Have you ever wondered how electrical devices work? The answer lies in electrical component research, which is the study of

UHF radios are essential equipment for anyone who needs to communicate over long distances. If you’re in the market for

Have you ever heard of an esd scanner? It’s a device that can protect your electronics from electrostatic discharge ESD,

When you’re zipping around town on your trusty mobility scooter, the last thing you want is for it to run

If you’re like most people, you probably use your mobile device a lot. And if you use your mobile device

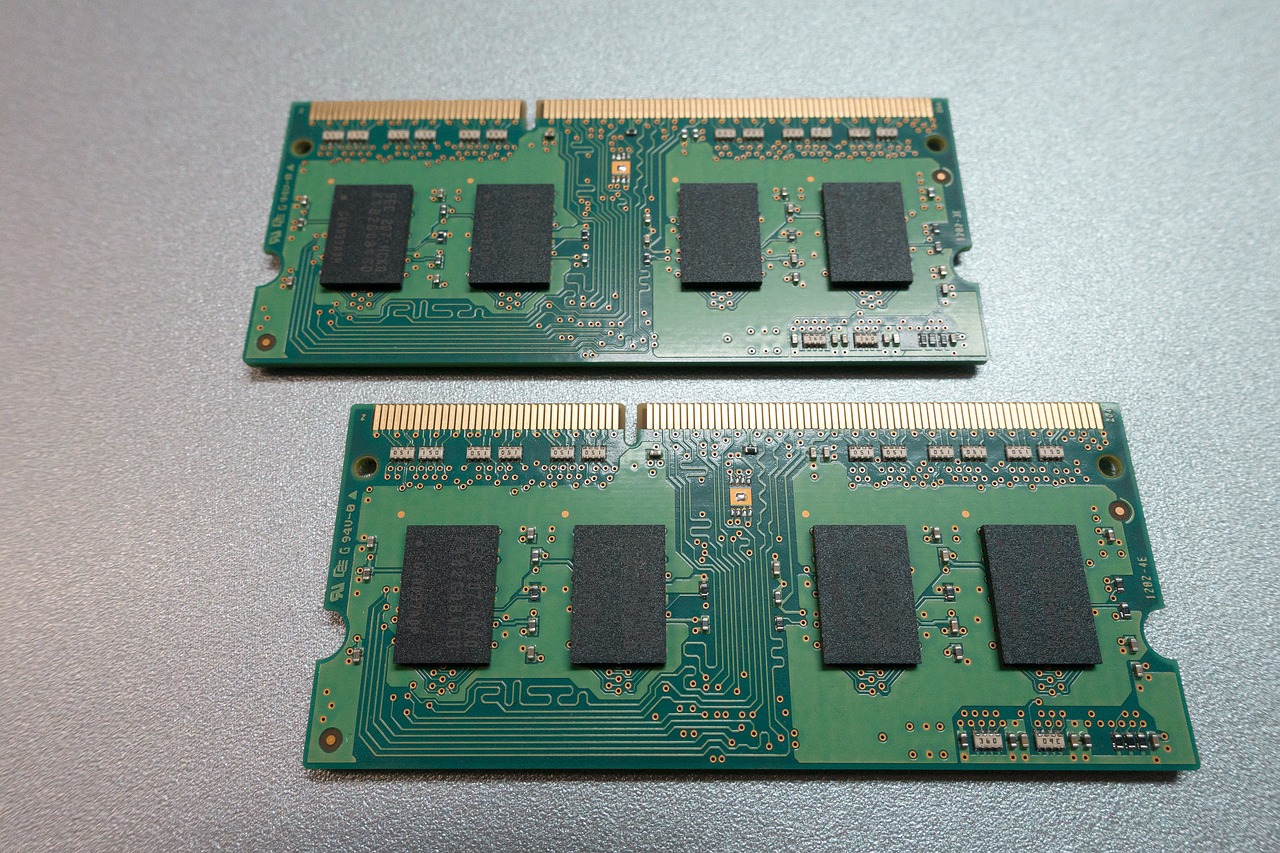

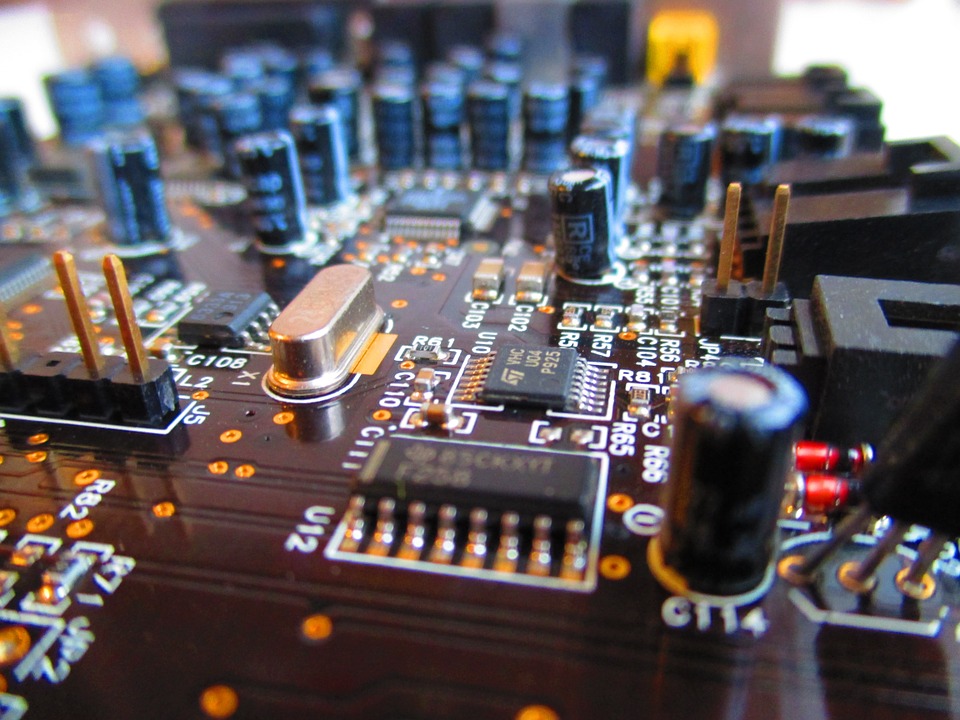

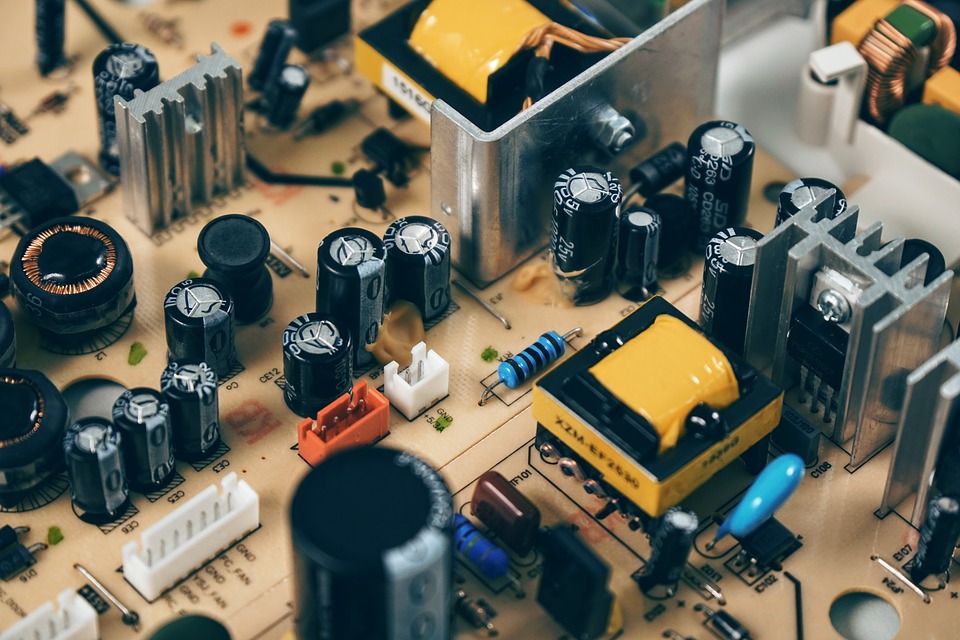

Many small and large companies and organizations make use of printed circuit board manufacturing services to manufacture their products. These

PCB Fabrication Assembly is the process of manufacturing various PCBs (Printed Battery Packages) from different raw materials. The process is

A PCB you are using in your finished product undergoes a thorough PCB fabrication assembly procedure. First, the PCB must

When you need PCB Assembly Services, check out a few of the quality PCB assembly services providers. One-stop Manufacturing and

You need reliable PCB manufacturing services when developing a hardware project. Most products now have some type of electronic component

Copyright © 2025 | Powered by Word-Weight

Copyright © 2025 | Powered by Word-Weight