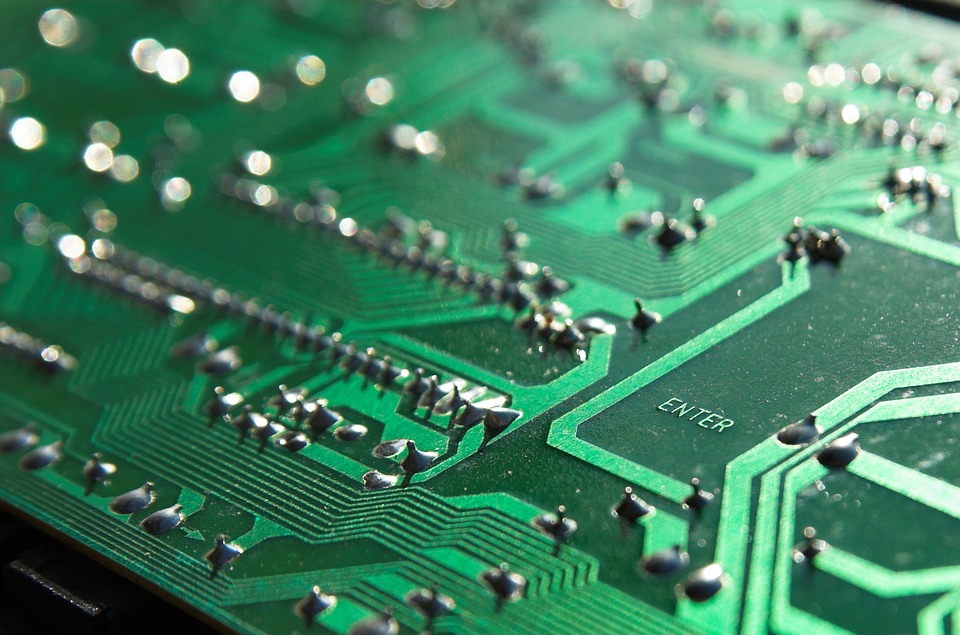

Professional PCB manufacturing used to be the sole domain of large companies with industrial-scale requirements. Thanks to technological developments, it is now possible for small to medium-scale enterprises to get access to high-quality factories at reasonable prices. Even hobbyists can create their own circuit designs and have specialists assemble the printed circuit board for them. The resulting pieces are much more polished than anything that an individual can produce on his own. It is also more durable and reliable. If you are thinking about getting this type of service, then study the process, look for good options, and get estimates for your project. Below are factors that influence a PCB manufacturing quote:

Number of Orders

All things being equal, getting more items means having to pay more to the seller. If you only need a few pieces of PCB to test your personal project, then you will not have to worry much about the cost. Prototypes are easy to produce and you can have them made as frequently as you want to after making the necessary changes. However, businesses that aim to get circuits into mass production at a small or medium scale will probably need to shell out a good sum of money. The bright side is that they can enjoy a lower price per piece than those making low volume orders.

Job Complexity

Check out online cost estimators so you can have an idea about the things that will push the price up or down. High complexity will definitely make the PCB more expensive. Calculators will ask you to provide the number of materials needed, the number of sides that require surface mounting, the number of thru-holes, the number of surface mount pads, and so on. If you introduce a lot of variables, then the assemblers have to do more work to combine everything in just the right way. It can be particularly hard if the components have to be soldered very close together.

Special Requirements

There might be special needs that have to be considered in the cost estimation. For example, the traditional way of securing components is to solder them with heat and lead. However, lead is a toxic substance that can damage the environment and poison living creatures. It is one of the major reasons why electronics are considered as hazardous materials that cannot be simply thrown in landfills. It makes disposal and recycling a big challenge. Fortunately, there are alternative lead-free processing methods.